So here’s last nights doings. Recheck each and every piston to be sure rings are right side up and gaps in proper places, locks in place, rod orientation correct, install in Total Seal ring compressor set to 4.090” ID. BTW I HIGHLY recommend this ring compressor, worked EXCELLENT!!

Install 2 piston assemblies, lube bearings snd journals with Driven Assembly Gel, measure and record length of each rod bolt, put cap in place, Tq to 40 ft lbs then 90, measure stretch on each rod bolt to insure its between the .005-.006” stretch wanted by Manley. Verify stretch gauge I made from a desk lamp clamp after every rod to calibration standard I made.

View attachment 46768

View attachment 46769

View attachment 46770

View attachment 46771

View attachment 46772

View attachment 46773

View attachment 46774

View attachment 46775

View attachment 46776

View attachment 46777

View attachment 46778

View attachment 46779

View attachment 46780

View attachment 46781

View attachment 46782

View attachment 46783

View attachment 46784

View attachment 46785

View attachment 46786

View attachment 46787

View attachment 46788

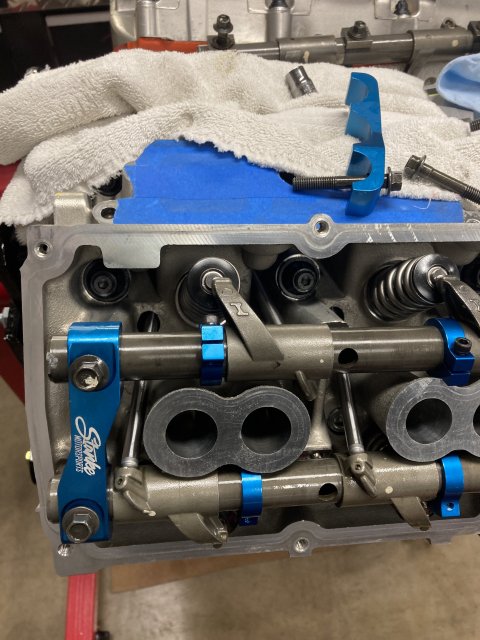

Check clearance between each rod set main journals, ensure oil squirters are not hitting pistons. Measure crank end play before and after all pistons are installed, measure piston rock BDC, measure Piston deck height clearance. All passed. Next step change springs, retainers, and locks in the heads to a higher RPM capable Comp Cams .630” lift kit.